For 30 years, our primary focus has been on improving production in the food and beverage industry. We will provide you with a flexible and proven solution that is the ultimate tool for managing all your production tasks. We place maximum emphasis on security, the recipe model of our system therefore complies with the ISA-88 standard, and during its installation we also address the cybersecurity of your corporate IT infrastructure.

Production automation and monitoring

Modern food production cannot do without a flexible, modular technology management system that responds skilfully to production needs. Thanks to our experience, we are able to upgrade your existing technological equipment and process units with long-term sustainability and precise monitoring in mind.

The results of continuous measurement are used to improve production efficiency. Measurement outputs provide effective insight into production through production data reports, which are then used to optimally adjust production equipment and processes.

Another important role is played by online monitoring of energy consumption, which, if the data is correctly evaluated, contributes to optimal energy use and avoidance of waste.

There is no need to change the entire production to achieve favourable results. Our systems upgrade service is affordable and won’t put a strain on your business.

.

Upgrade of technological equipment

It often takes less than you might expect to improve the quality and stability of production. In fact, your own production equipment may still be in good mechanical shape, but it is hampered by old or functionally inadequate control systems. In addition, the availability of spare parts also decreases over time. Thanks to our experience, we can modernize them with long-term sustainability in mind and not burden your production with longer shutdowns. Achieve great results with your existing production at a reasonable cost. Upgrade..

Cost reduction

Upgrading will help you reduce unplanned production downtime, maintenance time, and operating costs.

Highest convenience

We will propose to you the optimal technological solution from analysis, installation of new measuring and control elements, modernization of switchboards, development of new control system application software to commissioning.

Monitoring

We’ll introduce advanced production monitoring to ensure the efficient setup of production equipment and processes, optimal energy use, and waste avoidance.

Upgrade

We will also offer you an upgrade of your existing automation solution to improve its efficiency, extend its lifetime, and expand the possibilities for further system development.

What do typical solutions look like?

The most popular systems and solutions we offer to our clients in the beverage and food industry include process control technology, advanced energy monitoring, sanitation station operation, and syrup production automation. The use of OEE statistics for the management of production facilities is also very popular. We also offer specialized technological equipment for even more perfect production.

Freezing of spirits

Due to large temperature changes during transport or storage, sediment often appears in distillates, which can have a negative impact on your customers’ preferences. Our equipment for freezing spirits before bottling prevents this phenomenon and is therefore very popular. We are currently running it successfully on several installations. Since we know that every production has its own specifics, we are ready to customize the equipment to your exact needs.

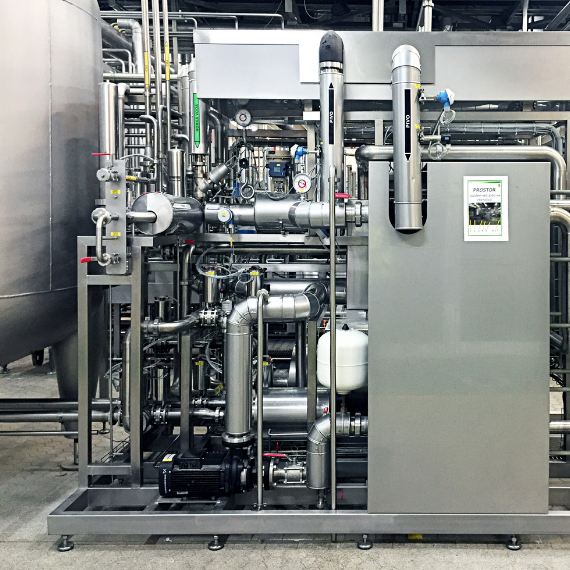

Pasteurization

Our long-standing specialization in the beverage and food industry allows us to develop and manufacture top-quality automatic continuous flow pasteurizers for beer, milk, and other beverages. We equip them with an advanced dynamic model of pasteurization control that will bring many benefits to your production.

Reducing costs and consumption

Our pasteurizers will reduce your thermal energy consumption and operating costs in the aftercooling section.

Stable control

The modern solution brings you easy and stable control of pasteurisation on the desired PU.

Quieter operation

Our dynamic pasteurization model calms the operation of the pasture itself and thus extends its lifetime.

Advanced reports

Our ECS Archive solution is also a part of the pasteurizer, offering you complete data collection from the operation.

Sanitation stations

A fully automatic or semi-automatic sanitation station is a prerequisite for maintaining product quality and safety throughout the entire production process. That’s why we’ve designed our sanitation station solution to simplify your sanitation management as much as possible, saving you time, operational costs, and offering detailed reporting.

Design and installation

We will design the sanitation station exactly according to your needs and the characteristics of the circuits and equipment to be sanitized.

Recipes and reports

Included in the delivery of the equipment is a system for complete data collection from the sanitation process and a user-friendly recipe system for sanitation procedures.

Automatic analysis

We analyse and evaluate compliance with the prescribed sanitation process and save you time in quality verification.

Optimization and savings

We will ensure that the sanitation of individual circuits and facilities is optimized in terms of sanitation quality, sanitation time, and water and sanitizer consumption.