We are here to boost your efficiency

For more than 30 years we have been building our technological know-how in the field of process equipment for the beverage and food industry. We design and supply technological equipment based on a high degree of automation. We deliver all solutions on a turnkey basis, from study and commissioning to integration. By upgrading and adjusting processes, we can boost the efficiency of your equipment, extend the life of your machinery and reduce operating costs.

Upgrade and increase of automation level

You don’t always have to buy new and expensive equipment to increase the quality and stability of your production. Thanks to our experience, we are able to upgrade your existing equipment and process units with long-term sustainability in mind. Simply having an upgrade leads to a higher automation level, achieving the optimal result at a reasonable cost. The results will not take long to come.

Cost reduction

Automation will help you reduce operating costs and the risk of human error.

High level support

We will design the optimal technological design and carry out all the work associated with the installation.

Upgrade

We can also offer you the upgrade of your existing automation solution to improve its efficiency and extend its lifetime.

Monitoring

We’ll introduce advanced production monitoring to give you maximum control over all phases of production.

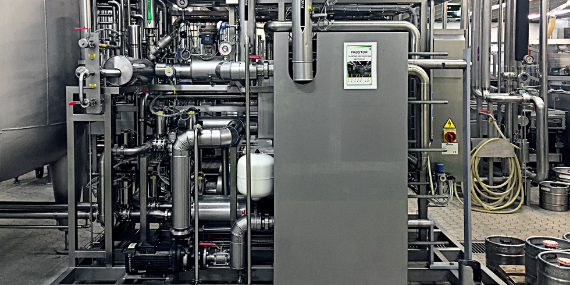

Continuous flow pasteurizers

Our long-standing specialization in the beverage and food industry allows us to develop and manufacture top-quality automatic continuous flow pasteurizers for beer, milk, and other beverages. We equip them with an advanced dynamic model of pasteurization control that will bring many benefits to your production.

Reducing costs and consumption

Our pasteurizers will reduce your thermal energy consumption and operating costs in the aftercooling section.

Stable control

The modern solution brings you easy and stable control of pasteurisation to the desired PU.

Smoother running

Our dynamic pasteurisation model ensures the smooth operation of the pasteurizer itself and thus extends its lifetime.

Advanced reports

Our ECS Archive solution is also a part of the pasteurizer, offering you complete acquisition of operating data.

Diatomaceous earth filtration of beer

We can provide you with comprehensive reconstruction and upgrade of the beer filtration process. Enjoy more efficient filtration from pumping from the cellar to dispensing into bright beer tanks, lower operator requirements, and higher beer quality. We will take care of the entire modernization, including the design of the appropriate degree of automation, measuring, and control elements.

Product stability and safety

The automation of the filtration process, together with modifications to the technology, brings, in particular, the stabilisation of quality and the assurance of product durability.

Reduction of operating costs

Thanks to the optimization of the filtration process, the operating costs of diatomaceous earth can be decreased and beer losses can be reduced.

Extension of filtration time

Proper dosing of diatomaceous earth and advanced control of the entire system also results in extended filtration times.

Sanitation and control

Process automation will ensure thorough sanitization of equipment and provide advanced reports and production records.

Automated tanker truck for tank beer delivery

We develop, modify and supply automated tanker trucks with advanced systems for distributing and bottling of tank beer. It is the most modern way to bring fresh beer of the highest quality to the table in front of the customer.

Fully automated

Only one driver is needed to operate the tanker truck, using a mobile device to select the tanks to take beer from. Thanks to advanced automation, the sanitation, filling, and delivery of beer are always carried out in accordance with the defined processes.

Maximum quality

The beer has the best possible conditions thanks to automatic sanitation and advanced pressurization of CO2 tanks from an aseptic cryogenic unit.

Accuracy

Dispensing with a precision to +/-0.5% according to legislation, and a document about the quantity actually received is issued to the customer. This also prevents the entire system from tampering and minimizes product waste and loss.

Savings

Reduction of logistics costs for smaller customers, savings due to the possibility of using their own CO2 for filling a cryogenic unit and reduction of filling time to a minimum.

Sanitation stations

A fully automatic or semi-automatic sanitation station is a prerequisite for maintaining product quality and safety throughout the entire production process. That’s why we’ve designed our sanitation station to make sanitation management as simple as possible to save you time and costs, and to offer detailed reporting.

Design and installation

We can design the sanitation station exactly according to your needs and the characteristics of the circuits and equipment to be sanitized.

Recipes and reports

The equipment includes a system for complete data acquisition from sanitation process and a user-friendly recipe system.

Optimisation and savings

We optimize individual circuits in terms of quality and sanitation time, including water and sanitizer consumption.

Automatic analysis

Using sanitation reports, we can evaluate compliance with the prescribed sanitation process, saving operators and lab technicians time in quality verification.

Adjustment of original gradation and carbonisation

The optimization of beer production is our domain. Therefore we design and manufacture equipment for continuous adjustment of beer gradation and carbonisation. Our goal is the highest quality and accuracy, which we achieve by using Anton Paar measuring instruments and a dynamic control model. We provide turnkey solutions and integrate all equipment into production units, including the ECS Archive database system with complete data acquisition of equipment operation.

Freezing of spirits

Our equipment for freezing of spirits before bottling prevents the phenomenon of minor haze after the liquor has been cooled down before consumption, which is why some liquor producers like to use it. We are currently running it successfully on several installations. Since we know that every production has its own specifics, we are ready to customize the equipment to your exact needs.